The flexibility, convenience, and costs of laser marking, engraving, or etching means it is used in almost every industry. The variety of materials suited to the use of laser technology has seen it embraced by businesses and industries across the globe to the extent few organisations could function without its use on a daily basis.

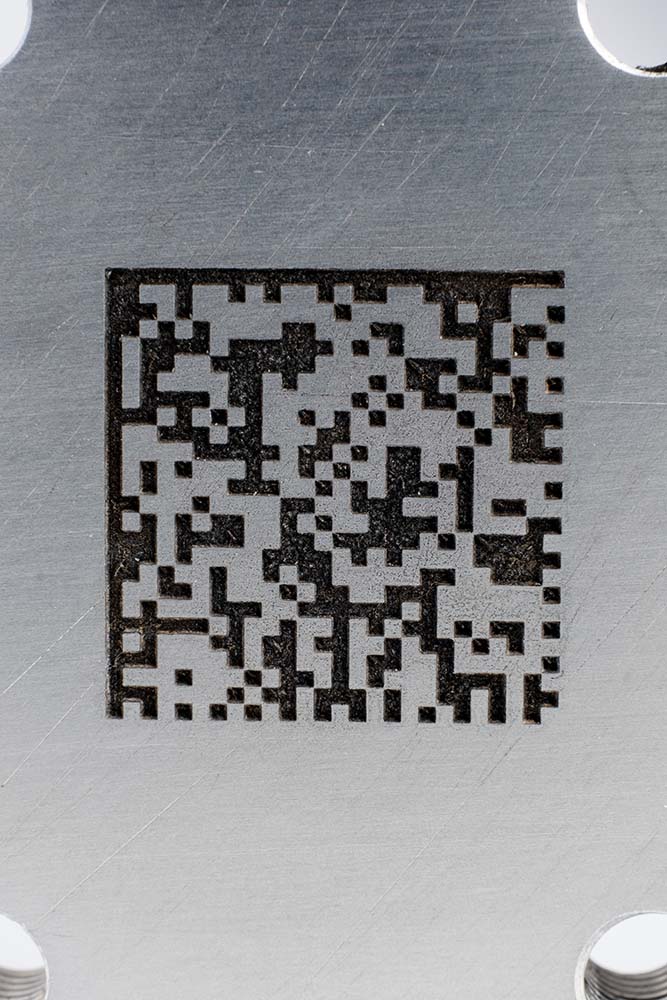

One of the major developments in the use of laser marking has been to improve the traceability of items. Incorporating barcodes, QR codes, serial and batch numbers, and other details allows the seamless tracking of items from their point of manufacture to the end user or application. International boundaries become insignificant, and a quick scan of the code delivers an instant and detailed account of where that particular item has travelled. The impact on supply chain efficiencies has been immeasurable.

In many instances the need for laser marking is stipulated by law, where an item must be permanently marked with specific information related to its origin, operation, or quality to allow its use. One reason for this is to preserve standards in safety, where component and sub assembly parts must adhere to strict levels of manufacture to be used in certain industries.

The food and hospitality industry uses laser technology to create bespoke signage, menus and other promotional tools to help businesses differentiate themselves.

Point of sale manufacturers are frequent users of laser technology for the creation of innovative in-store displays to draw attention to specific products or services.

Permanent marking is required on small arms and ammunition to ensure full traceability and adherence to legal statutes, as well as to comply with compulsory registration of ownership.

Organisations in both the public and private sectors are increasingly engaging laser technology for creating ID cards and smart cards to combat fraud.

Our extensive range of cutting-edge laser machinery enables us to provide the exact solutions to your needs and ensure your products comply with industry requirements and deliver the necessary detail with precision and clarity.

With its high levels of precision, versatility and durability in the harshest of environments, laser marking is an essential piece of technology widely used across the engineering sector. It has the ability to make permanent marks across a broad range of materials including:

The process involves using a highly focussed laser beam to change the surface property of the material that then creates highly resistant marks that can withstand wear and tear, acids, chemicals and extreme temperatures.

Across the engineering sector, components are typically working in the harshest of environments and as such require laser markings that are incredibly durable. Crucial for identifying components, the markings also aid traceability and quality control of:

All of these need to retain their legibility throughout the lifecycle of the product they feature on. This high level of traceability also ensures they are complying with industry standards and regulations.

Detailed company logos that require some level of graphic also benefit from the precision of laser marking. Intricate designs and information show more clearly due to the accuracy and high resolution of laser marking, and the no-contact method of this tool doesn’t cause any mechanical stress that could impact performance.

The permanent marking of parts is pivotal across the engineering market where the need for part identification and traceability in manufacturing is vital. In particular, the demand for precise laser marking to engrave goods with batch numbers, part numbers, logos, and other product information has grown over the years as laser marking technology has evolved.

Laser marking across the engineering market ensures the manufactured goods are compliant with industry regulations, meet quality control standards, and reduce the risk of counterfeiting. The process of laser marking provides unrivalled durability, with marks that withstand acids, chemicals, and general wear and tear in what are often extreme environmental conditions in industrial settings.

Employing cutting-edge laser technology provides manufacturers with high-speed processing that doesn’t compromise the quality or integrity of the marked components. This efficient tool is proving extremely beneficial in high-volume production sectors that rely on detailed laser marking for a number of manufactured products.

We specialise in laser marking, engraving, and etching for clients in the aerospace market. A certain level of sophistication is required in the techniques used to protect against industrial tampering and counterfeit parts.

Due to the environments that aerospace parts operate in, the industry benefits from laser marking’s ability to produce high-contrast markings that can withstand extremely high temperatures, pressure variations, and exposure to corrosive substances. Critical and important information therefore remains legible, which is vital for safety and compliance.

It is commonplace for companies to look for ways to raise their brand awareness and profile whilst also seeking to increase their customer base. One popular and cost-effective solution is to permanently mark promotional merchandise with the brand logo and message. With quick production times and low operating costs, branded items keep the company name at the forefront of people’s minds, with many items being used in day-to-day life; for example, pens, tech accessories, mugs, water bottles, and mouse mats, to name a few.

Laser marking in such a way allows for precision and durability on a vast range of materials. From metal and plastic to wood and glass, our service at Laser Marked ensures your promotional items are high-quality and long-lasting. We can also cater to different target audiences with versatile options branded with a professional and polished finish.

As laser marking has evolved over time, the technology is now advanced enough to permanently apply product information and codes onto the surface of medical equipment and tools without creating any grooves in the process. This is important as it prevents bacteria from getting trapped and impacting the sterility of the item.

The precision, safety, and quality of laser marking meet the necessary stringent industry standards for ensuring the identification and traceability of medical devices. Vital for maintaining comprehensive records, this depth of traceability helps track the lifecycle of each tool, which is essential for patient safety and regulatory compliance. Additionally, laser marking is durable and resistant to wear and sterilisation processes, ensuring that the information remains legible throughout the product's use.

The defence industry holds within it a broad range of products that are manufactured with a diverse mix of materials including metal, plastic, ceramic, and composites – all used for their unique properties to meet specific requirements. Whether a weapon, ammunition, or advanced satellite or instrument display panel, the item must be coded to highlight critical product information to meet the highest safety standards and compliance across the defence sector.

Traceability in the defence sector is vital. It facilitates the precise tracking of each component's origin, production history, and usage, which is extremely important for maintaining quality control and accountability. This highly detailed coding helps identify and manage potential issues quickly, enhancing overall safety and operational efficiency.

Furthermore, the marking of critical information on these materials supports effective communication within and between organisations, ensuring that everyone involved has access to the necessary data for informed decision-making.

Across the science sector, laser marking offers a safe, clean, and repeatable process that is essential where small details are so important. The clarity and accuracy of the markings that are lasered onto the equipment must be perfect for the fields in which they are used.

Despite being small, the markings going onto devices used in scientific environments must be flawless to ensure that all component parts are easily identifiable and traceable. This level of precision can only be achieved with laser marking technology, enabling the application of intricate codes and serial numbers without compromising the integrity of the material.

Furthermore, the repeatability of laser marking ensures that each item is marked consistently, maintaining high standards of quality control. This is vital for regulatory compliance and for the seamless operation of manufacturing processes. The clean nature of laser marking, which avoids the creation of grooves or residues, further ensures that the marked surfaces remain sterile and free from contaminants.

Across the commercial and leisure marine industry, there are many common applications that include ID plates, control panels, cabinets, and wood furnishings. These parts often need precise identification along with tracking information to comply with maintenance and operational requirements.

To adhere to industry regulations, markings are also regularly needed to meet environmental standards. Laser marking allows accurate labelling and aids the quick identification of parts, streamlining repairs and replacements. Additionally, marine vessels' control panels need clear and durable markings to ensure safe and effective operation. Within the vessels themselves, wood furnishings and cabinetry benefit from long-lasting yet aesthetically appealing markings that enhance the overall quality of the marine environment.